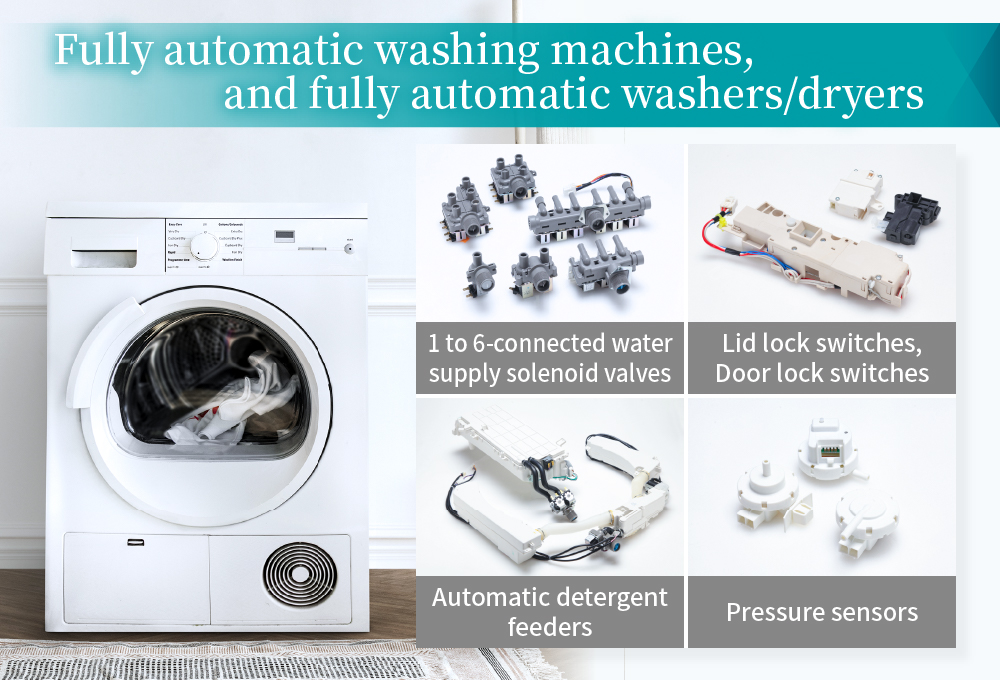

Core technology of Techno EXCEL that can freely control water, air, and liquid

We support high functionality and multifunctionality from within through our diverse elemental technologies.

From the coveted high-end models to the standard models, home appliances and professional equipment that are indispensable in our daily lives. Various technologies which we have created and cultivated for many years, such as fluid control technology and precision processing technology, have been adopted. In addition to responding to the demands of our clients, we are also focusing on the development of new technologies while looking ahead for the needs of end users.